Terfenol-D

The name Terfenol originated from the metallic elements, Terbium (TER) and Iron (FE); and the discovering organization, Naval Ordnance Laboratory (NOL). Dysprosium (-D) was added as an alloying addition later to reduce the magnetic fields required to induce the magnetostrictive response. NOL, now known as the Naval Surface Warfare Center – Carderock Division (NSWCCD) developed Terfenol-D for high power sonar offering greater bandwidth and reliability over legacy technologies. TdVib holds key patents and licenses for many Terfenol-D applications, including exclusive worldwide licenses to manufacture several types of Terfenol-D materials. TdVib is the world’s leading supplier of Terfenol-D materials and products. Additionally, TdVib provides assistance with the design and manufacturing of Terfenol-D driven products.

Physical Properties

Physical Properties

Terfenol-D’s physical properties are provided in the table. Terfenol-D exhibits a large magnetostrictive and magnetic flux density response versus applied magnetic field over a large range of compressive stresses. The following graphs are representative of Terfenol-D produced by TdVib.

In addition, TdVib can tailor the Terfenol-D composition to allow for a wider operating temperature range. By adjusting the Tb:Dy ratio large magnetostriction values can be achieved at temperatures as low as -200°C and as high as 200°C.

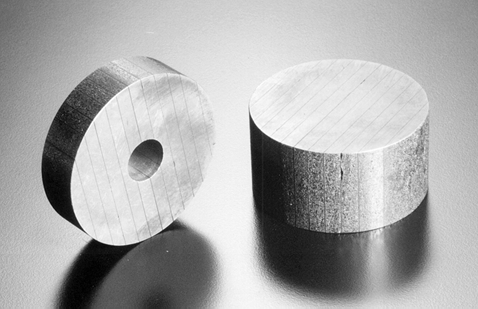

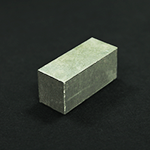

TdVib provides Terfenol-D ready-to-use, lowering the effective cost to our customers. TdVib’s patented crystal growing machines produce solid metallic rods. Customer specific geometries are produced by our unique machining processes. Typical Terfenol-D shapes and sizes are provided below.

Available Terfenol-D Shapes and Sizes

- For smaller sizes and in large quantities, square cross sections are often more cost effective than round cross-sections.

- 2mm square, 3mm square and 4mm square rods are common sizes produced by TdVib.

Have questions or want a quotation?

Contact TdVib for a quotation on the quantity and configuration needed. Or work with us to optimize performance and cost for your application

Comments are closed.