Galfenol

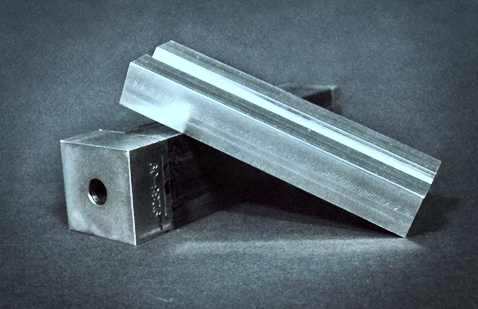

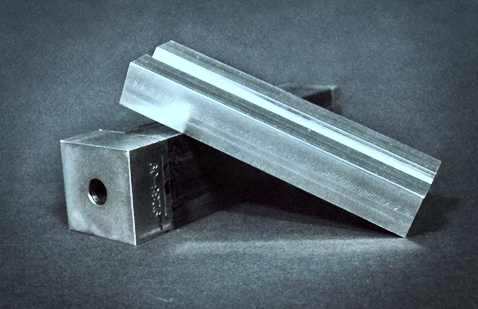

Heavily laminated square Galfenol sticks with a drilled through hole.

Galfenol is a magnetostrictive alloy comprised primarily of the elements iron (Fe) and gallium (Ga). It was discovered in 1999 through collaborative research efforts between the Magnetic Materials Group at the Naval Surface Warfare Center Carderock Division (NSWCCD) and the DOE’s Ames Laboratory. Motivation for its discovery was led by the presence of two other magnetostrictive materials, nickel (Ni) and TERFENOL-D. It was hypothesized that other magnetostrictive alloys had to exist that combined the mechanical robustness of Ni and the giant magnetostrictive response of Terfenol-D.

Galfenol exhibits a unique combination of mechanical and magnetostrictive (magnetic) properties that legacy smart materials do not. The table shows some of Galfenol’s magnetic and mechanical properties. In addition, the Galfenol Public Release provides a primer on current processing techniques and standard forms, compositions produced by TdVib, and unique shapes that have been fabricated using Galfenol alloys.

It should be noted that research is on-going in developing new processing methods to fabricate Galfenol components. This includes rolling the material into sheet form, wire drawing, and additive manufacturing. TdVib is always on the look-out for possible partners to help advance these next-generation manufacturing methods. If interested, please inquire using the Contact link at the bottom of this page.

Galfenol Public Release

Galfenol can be processed such that an internal, customized pre-stress is built into the material. This built-in pre-stress, commonly referred to as stress-annealing, allows the material to display a magnetostrictive response while under tensile loads exceeding 50 MPa. Magnetostriction and magnetic flux density versus magnetic field plots are provided for TdVib produced Galfenol in the following states:

Galfenol As-grown, Non-Stress Annealed

Galfenol Stress Annealed - Tested Under Compression

Galfenol Stress Annealed - Tested Under Tension

Galfenol’s ability to function while in tension, mechanical robustness and high Curie temperature (600 °C) is attracting interest for the alloy’s use in mechanically harsh and elevated temperature environments. Applications actively being investigated include transducers for down-hole use, next generation fuel injectors, sensing and

energy harvesting devices.

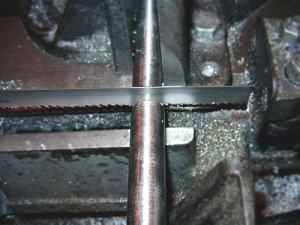

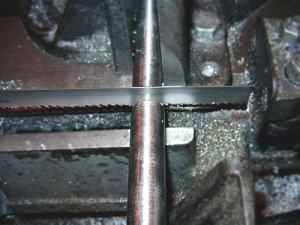

Galfenol rod being sectioned on a metal cutting saw.

Galfenol rod sectioned on a metal cutting saw

Available Galfenol Shapes and Sizes

Solid Rods

- Diameters up to 23mm with a maximum length of 260mm or less.

- We keep an inventory of 23mm diameter rods that customer specific sizes and shapes are produced from.

Laminated Rods

- Laminated rods are used for eddy current control in higher frequency applications. TdVib will recommend a lamination thickness based on the operating frequency of your application.

- Minimum lamination thickness available for Galfenol is 0.010”.

Holes and Custom Shapes

- Solid and laminated rods are can be produced with axial holes for active cooling or prestress.

- Holes can also be produced in plates and other shapes.

- Various non-routine shapes are frequently produced with attention paid to the axis of maximum magnetostriction.

Have questions or want a quotation?

Contact TdVib for a quotation on the quantity and configuration needed. Or work with us to optimize performance and cost for your application

Contact

Comments are closed.